ARCUTT – Cutting units by ARTECC®

ARCUTT Z10 – Z12 – Z14 – Z15 – Z16 – Z18 – Z20 – Z22 – Z25

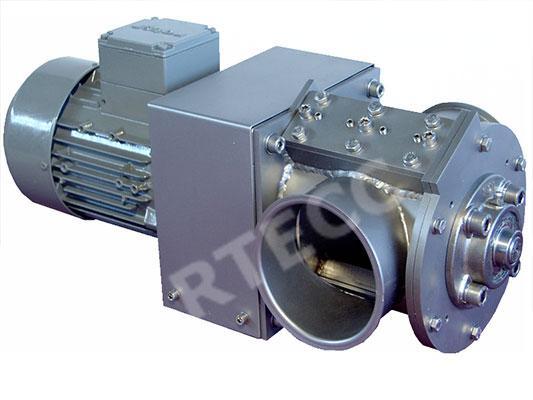

All variants available as stainless steel and L-version

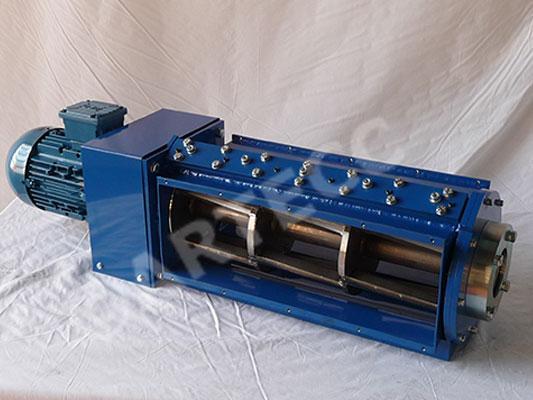

As a future-oriented manufacturer, we produce eight different standard sizes for DIN pipe diameters for the world-wide market. The unique design of our crushing devices significantly reduces air resistance in pipe systems of extraction systems, thereby offering maximum throughput capacities for transporting air and solid materials when handling process waste.

Our rotor shafts are manufactured ranging from single-blade to ten-blade versions, operated at different speeds for electric motors or integrated frequency transformers. Desired cutting lengths are easily achieved, and variable perforated sheets can be used to shred various materials.

Hard metal quality for the longest possible service life is part of our standard, as are stainless steel cutters for hygienic areas. L-versions round off our portfolio through the elongated design of all device sizes.

Areas of application

- Cutting of residual material of any kind

- Edge cuts (trimmings)

- Punch frames (also self-adhesive)

- Production shavings

- Empty packages

- Production offcuts

- Rework

Cuts virtually any material

- Paper

- Cardboard packaging

- Plastic

- Textiles

- Light metals

- Rubber

- Wooden furnishings

- And many more!

Large profile

The large profile in the casing ensures a high throughput performance. This benefit is especially apparent when processing lead frames or comparable large-volume waste material, such as textile or fleece.

Stainless steel

Complete units made of stainless steel are well-suited for use in the foods or pharmaceutical industry.

Conversion and expansion

Extraction systems without cutting units can be easily converted any time, older devices can be easily replaced within existing extraction systems without any problems. That way, the same energy consumption of the fans can achieve a higher and steadier extraction performance.

New models and special equipment

Rotation monitors or repair switches, for example, offer comfort and protection when used. Increasing production speeds and new materials require adaptable cutting technologies. That is why we as manufacturers offer special, future-oriented device types while continuing to work on future developments and special models.

Our innovating in cutting

- Constructive reduction of air resistance in casing

- Single-row setting of the stator blades

- Low installation weight of the complete unit

- Robust weld design of the casing

- No air turbulence within the device

- The open rotor enables full pipe passage and free removal of the cut material

- No Venturi effect in the casing but instead free air throughput at maximum material speed

Only available from us!

Original parts are only available directly from us. All original component groups, spare parts and individual parts guarantee proper fit and quality.