Cut’n Compact

Single-station and multi-station solutions for the extraction of edge trimmings and lead frames in non-stop operation. The material is highly compacted by an integrated compacting unit and run off as endless strand. The ARCUTT crushing technology helps to cut all endless waste into small pieces for compacting purposes.

Punched grid processing

When disposing of label lead frames on printing machines, the mobile extraction unit with a 180° infinitely variable and height-adjustable retention arm ensures flexible alignment to any printing machine. Conversion to a new work space is effortless as only a power connection needs to be established.

All components of the cutting devices, including the compressed air, have already been preinstalled in the system and can be connected without any effort.

Alternatives

ARTECC® extraction solutions with integrated compacting close the gap between small single-station solutions and central extraction systems.

Product discharging options

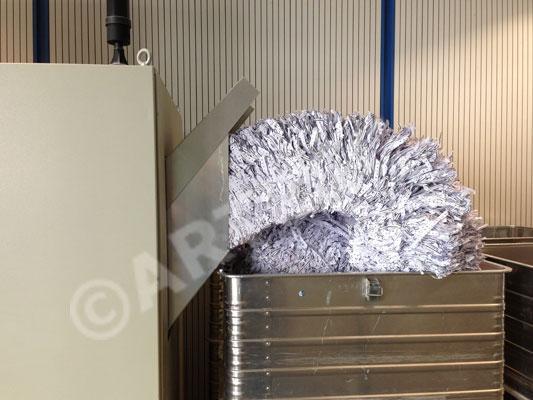

The compacted material leaves the system as endless strand and can be directly transported into roll containers via a material slide or provisionally stored on roll tracks or pallets until picked up.

Processing waste volume

The compacting units are available with different performance capabilities and in different sizes, capable of adapting to any volume of material.

Indoor solutions are also conceptualized as centralized extraction systems and are capable of processing edge trimmings and punched grids.